When it comes to safeguarding worksite edges and preventing falls, safety is never negotiable. For professionals seeking reliable, efficient solutions, the Aluminium Beam Clamp Edge Protection System for Sale in Saudi Arabia offers a significant advancement over traditional guardrails. This system, designed for ease of installation and robust performance, is reshaping how edge protection is approached on construction sites, industrial facilities, and maintenance projects.

Traditional guardrails have been the go-to method for edge safety for decades. However, advancements in materials and design have introduced aluminium beam clamp systems that not only meet but exceed many of the performance and safety standards expected in the industry. Below, the key benefits of aluminium beam clamp edge protection systems are outlined, demonstrating why they are becoming the preferred choice for many professionals.

1. Lightweight Yet Durable

One of the most notable advantages of aluminium beam clamp edge protection systems is their lightweight nature. Aluminium as a material combines strength with reduced weight, making it easier to handle, transport, and install compared to steel guardrails. This lighter profile helps reduce worker fatigue and speeds up installation, which can translate into lower labour costs and quicker project completion times.

Despite their lightness, aluminium systems do not compromise on durability. They resist corrosion exceptionally well, especially in harsh environments such as coastal areas or industrial sites with chemical exposure. This corrosion resistance ensures a longer lifespan and less maintenance compared to traditional steel guardrails, which may rust and degrade over time.

2. Quick and Flexible Installation

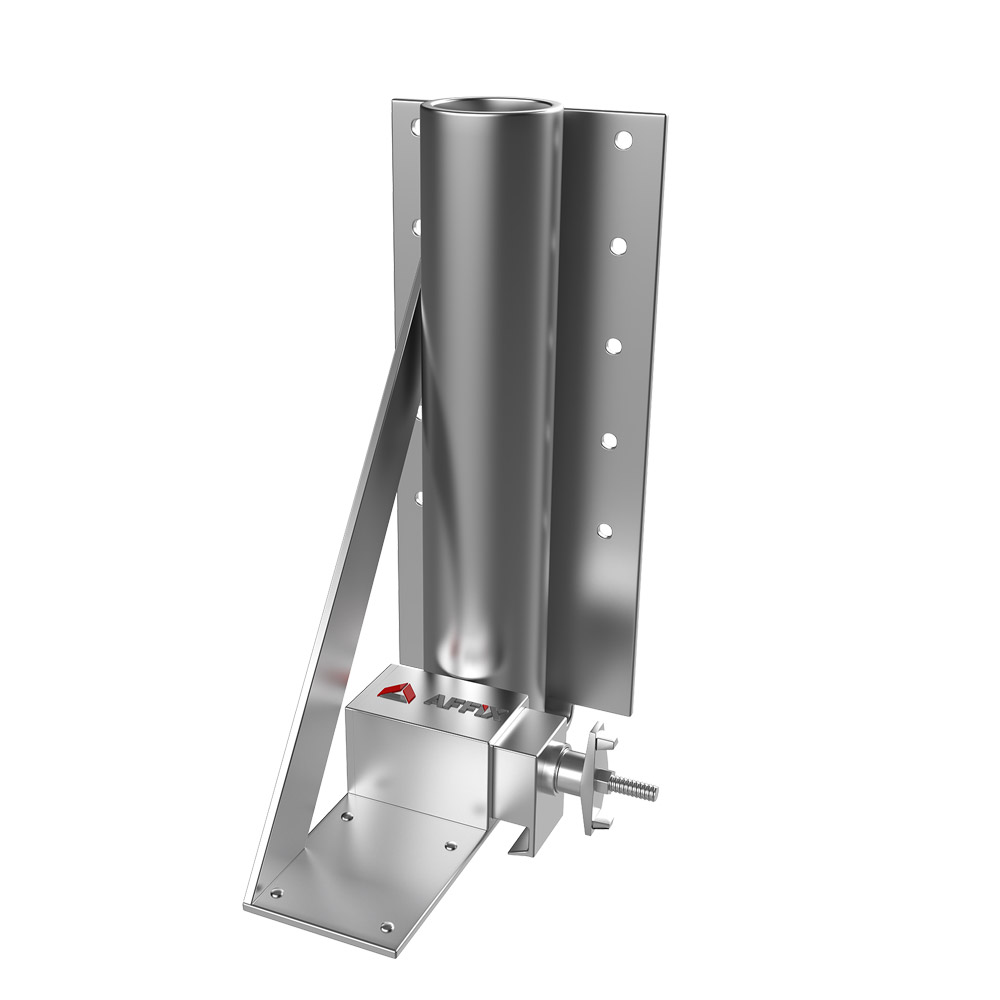

Traditional guardrails often require drilling, welding, or permanent fixtures to attach securely to edges. This process can be time-consuming, labour-intensive, and sometimes damaging to the underlying structure. Aluminium beam clamp systems, however, are designed to clamp securely onto existing beams or edges without the need for permanent alterations.

This clamp mechanism allows for swift installation and removal, offering greater flexibility for temporary worksites or projects with changing configurations. Workers can reposition or remove the edge protection as needed without specialised tools or extensive downtime. This adaptability makes aluminium beam clamp systems ideal for a range of applications from construction to maintenance and refurbishment projects.

3. Enhanced Safety Compliance

Safety standards and regulations in construction and industrial environments continuously evolve, demanding reliable edge protection solutions. Aluminium beam clamp systems are engineered to meet or exceed these stringent safety requirements, providing a secure barrier that significantly reduces the risk of falls.

Their design incorporates strong locking clamps and robust profiles that ensure stability even under heavy loads or high wind conditions. Unlike some traditional guardrails that may become loose or unstable over time, these systems maintain consistent performance, offering peace of mind for site managers and safety officers.

4. Cost Efficiency Over Time

While initial costs for aluminium beam clamp edge protection systems may be slightly higher than traditional guardrails, the overall cost efficiency becomes evident over time. The low maintenance needs and long-lasting corrosion resistance reduce replacement and repair expenses.

Additionally, the reduced installation and removal time translates into labour savings. Projects benefit from faster mobilisation and demobilisation of safety equipment, allowing teams to focus on core activities without prolonged delays. These factors contribute to a lower total cost of ownership, making aluminium systems a financially smart investment.

5. Versatility Across Various Applications

The aluminium beam clamp edge protection system is versatile enough to be used in a wide variety of settings. Whether on high-rise construction sites, industrial platforms, roofing works, or temporary scaffolding structures, these systems can adapt to different edge profiles and beam sizes.

The modular design allows components to be configured in multiple ways, accommodating unique site requirements. This versatility means fewer custom parts and less need for specialised components, simplifying logistics and inventory management.

6. Reduced Environmental Impact

Using aluminium in edge protection systems offers environmental advantages as well. Aluminium is highly recyclable, and many systems use recycled aluminium in their manufacture. When compared to traditional steel guardrails, aluminium's lower weight also means reduced fuel consumption during transportation, minimising the carbon footprint associated with delivery and handling.

For companies prioritising sustainability and environmental responsibility, switching to aluminium beam clamp systems aligns with green construction principles and responsible resource use.

7. Improved Ergonomics and Worker Safety

Traditional guardrails often require workers to engage in strenuous lifting and positioning, which increases the risk of musculoskeletal injuries. Aluminium beam clamp systems, being lighter and easier to manipulate, contribute to improved ergonomics on site.

By minimising physical strain, these systems help reduce worker fatigue and injury risks related to manual handling. Safer and more comfortable working conditions contribute positively to productivity and overall site morale.

8. Sleek, Modern Appearance

Though safety takes precedence, aesthetics can matter in certain projects, especially when edge protection is visible to clients or the public. Aluminium beam clamp systems feature a sleek, modern look that projects professionalism and attention to detail.

This contemporary appearance can reflect well on contractors and site managers, emphasizing their commitment to using advanced, high-quality safety solutions.

Why Choose Affix Gulf Scaffolding Manufacturing LLC?

Affix Gulf Scaffolding Manufacturing LLC is committed to delivering premium aluminium beam clamp edge protection systems tailored to the demanding needs of the Saudi Arabian market. Our products combine innovation with rigorous quality control, ensuring that each system performs flawlessly in even the most challenging environments.

Choosing Affix Gulf means opting for:

-

Reliable, tested safety equipment built to last and perform.

-

Local availability, ensuring prompt delivery and support.

-

Expert guidance and after-sales service focused on your project's success.

-

Competitive pricing without compromising on quality.

-

Custom solutions to fit unique project requirements.

With Affix Gulf Scaffolding Manufacturing LLC, safety meets efficiency and reliability. Our aluminium beam clamp edge protection systems stand as a trusted choice for contractors and professionals looking for the best in edge safety solutions across Saudi Arabia.